The european brandname for digital watermark technology

To meet EU recycling goals and increasing demand for food safe recycled granulate, we need to solve the sorting problem: how can we extract valuable food grade plastics from the waste stream?

To meet EU recycling goals and increasing demand for food safe recycled granulate, we need to solve the sorting problem: how can we extract valuable food grade plastics from the waste stream?

The sorting problem

40% of the total consumer waste volume is food packaging which can not be recycled back to food except for PET bottles.

The reason for this is that current sorting technology based on Near Infrared (NIR) cannot sort on food vs non-food, nor on e.g. black packaging, packaging with reflective or metalized surfaces and on different types of layers.

As a result, PET fractions for instance can be sorted by type of material but can only be downcycled or incinerated and therefor have very little value.

Sorters even pay to have large volumes incinerated.

Today, even 100% RECYCLABLE food packages are not being RECYCLED but incinerated!

The recycling problem

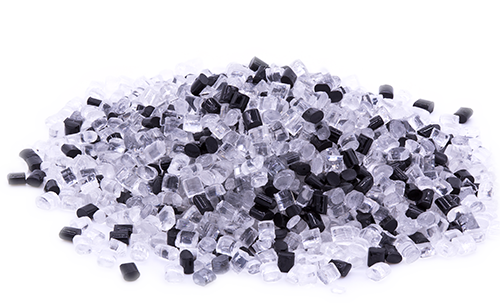

Demand for food grade & food safe recycled granulate is growing rapidly as most brand owners and retailers ask the packaging producers to use at least 30-35% recycled plastics in new packaging. The limited availability, in particular of food grade recycled PET, is a major problem.

Currently, the supply of rPET can only come from PET bottles. Refund systems for bottles are a partial solution in some European countries, but cannot meet the increasing demand for recycled PET.

According to EFSA-regulations, Food to Food recycling is only allowed when less then 5% of the recycled content is non-food. Current NIR technology cannot separate food from non-food material.

For extending the recycling life of plastic packaging, black packaging is welcome. NIR however cannot sort on black.

Closing the loop IS ESSENTIAL AND can only be ACHIEVED if all stakeholders take responsibility and work together.

Brand owners

& retailers

REDESIGN PACKAGING

TO MAKE THEM 100% RECYCLABle

What do brand owners and retailers need to do to make it possible for the supply chain to use and produce recycled granulate and to contribute to the reduction of CO2 emission?

Packaging producers

& converters

Use 30% RECYCLED plastic and embed DIGITAL WATERMARKS

What do producers and converters need to do to insert digital watermarks (3D/2D) into new packaging in order for sorters to sort on valuable food grade packaging?

EPR policy

& sorters

UPGRADE sorting technology to sort on food

How can sorting plants sort on food grade packaging as input for recyclers to make (valuable) food grade /-safe recycled granulate?

Recyclers

RECYCLE food safe fractions to

R granulate

What do recyclers need from the sorters to be able to produce recycled granulate to meet increasing demand for recycled granulate according to EFSA requirements?