The european brandname for digital watermark technology

In 2019 the Ellen MacArthur Foundation found DIGITAL WATERMARKS to be the most promising technology to solve the sorting problem.

In 2019 the Ellen MacArthur Foundation found DIGITAL WATERMARKS to be the most promising technology to solve the sorting problem.

The solution

FiliGrade founded the technology for the digital watermarks proof-of-concept for HolyGrail 1.0.

Although the original concept of ‘smart packaging’ opens up other possibilities such as consumer engagement, it is quite complex and expensive as a sorting solution.

Therefore, FiliGrade further improved and developed its digital watermark technology dedicated for sorting.

To succeed, the technology should be simple, reliable, cheap and easy to integrate in existing sorting plants.

The acceptance of CurvCode by brand-owners and marketeers is of paramount importance. Packaging carrying CurvCode has excellent machine-reading capabilities. At the same time, the visual impact of CurvCode is generally negligible in the eyes of the consumer.

Curvcode

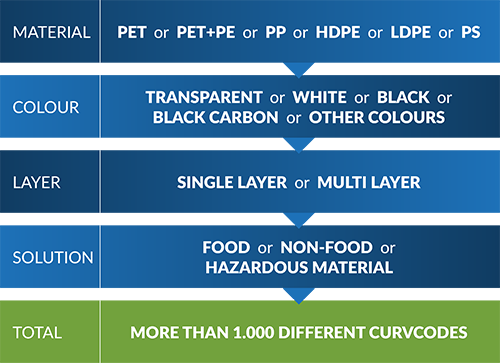

The solution is CurvCode, a set of codes for print and rigids:

This particular code is used for sorting PET, neutral transparent, single layer, food packaging.

In March 2021 the technology was independently assessed by two Dutch Universities at technology readiness level 6.

CurvCode is not only developed for sorting plastics, but also for fiber-based packaging (for instance drinking cartons with different types of layers), bio-based packaging, flexibles etc, as well as for non-packaging applications.

Closing the loop AND SORTING ON FOOD vs. NON-FOOD ARE ESSENTIAL FOR a circular plastics economy

TechnoloGy Readiness Level 6

In March 2021 the CurvCode technology was tested for rigid packaging according to a test protocol (static testing and dynamic testing at different belt speeds up to 3,11 m/s) and independently assessed by two Dutch Universities at technology readiness level 6.

As it is relatively easy to insert and detect (2D) watermarks in print (IML, sleeves, wraparounds, labels, flexibles), this test focussed on PP and PET rigid plastic packaging in different colours (transparent, white, black, other colours) with embossed (3D) CurvCodes.

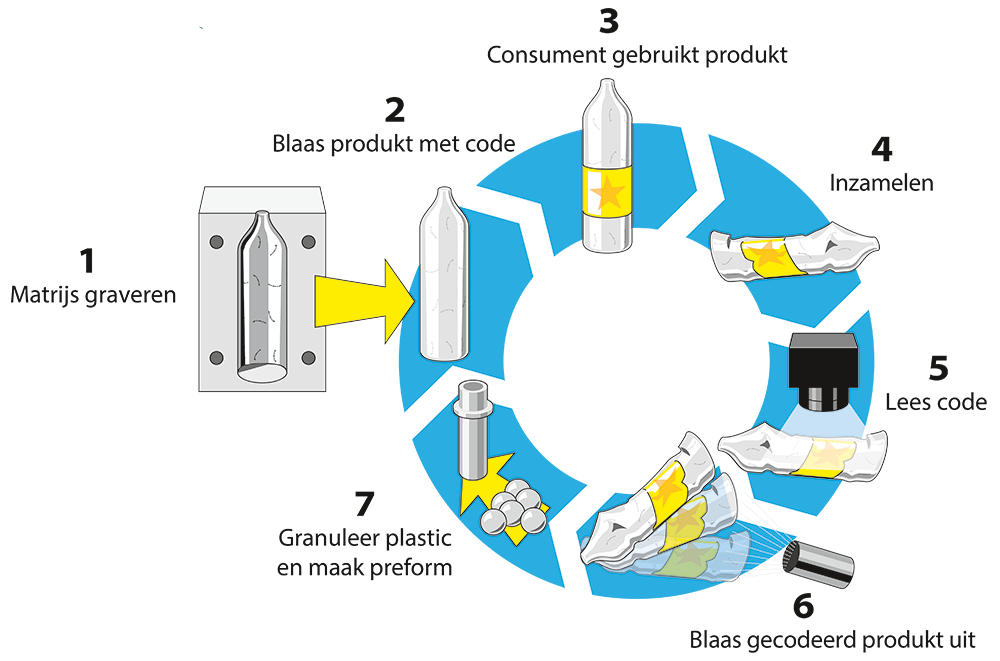

Embossed (3D) OR MATTED codes

- For embedding in plastic rigid packaging, flexibles, fiber-based and

bio-based packaging. - In plastics, CurvCode can be embossed (bumps and recesses) through engraving ‘dots’ into the mould. On glossy sufaces, the code can also be matted.

- Suitable for thermoforming, injection moulding and blow moulding.

Printed (2D) codes

- For embedding in all printed surfaces, such as IML’s, sleeves,

wraparounds, stickers, labels, drinking cartons, flexibles. - Codes are (nearly) invisible and can easily be inserted into the

artwork, using existing colours. No extra ink or varnish is needed. - Suitable for all printing techniques: rotogravure, flexo, offset, digital.

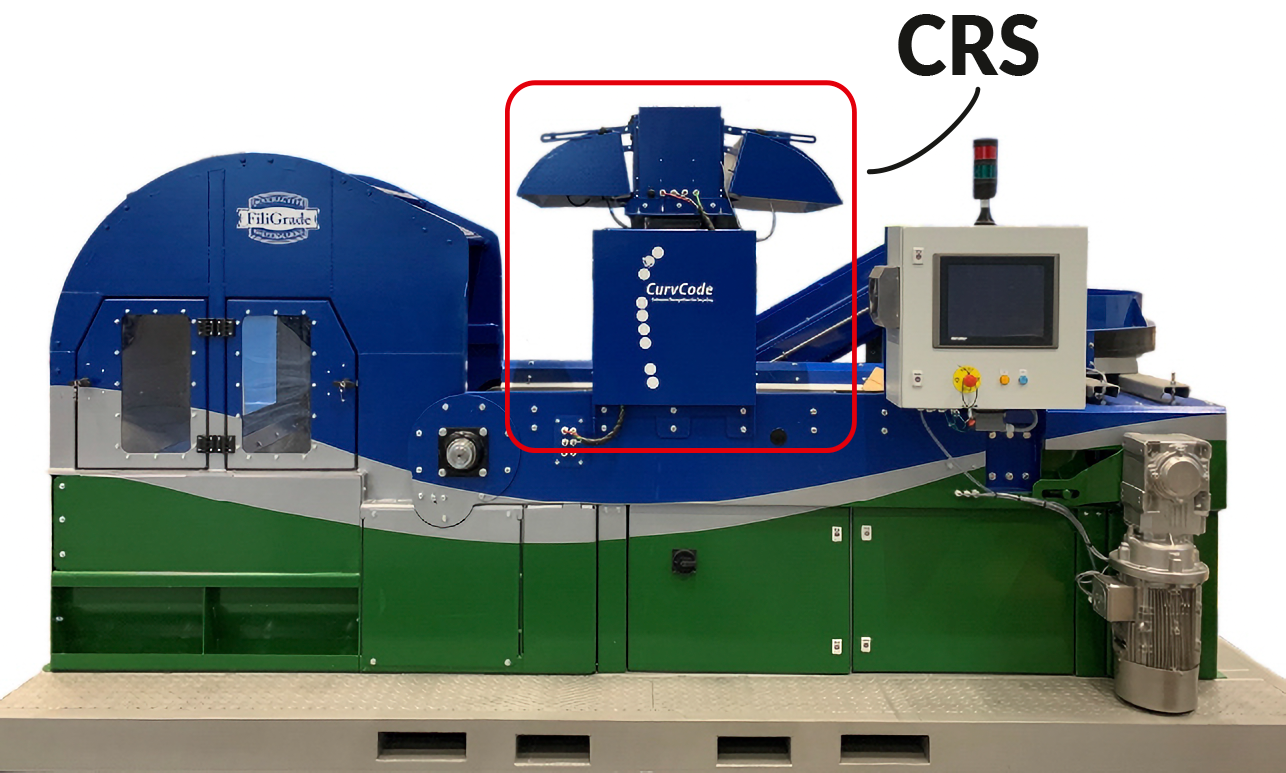

Sorting plastics with CurvCode (3D/2D)

- With current NIR technology it is not possible to sort on black (carbon) and on food.

Both are essential to increase RECYCLING rates of plastic packaging. - Sorters can and will only sort on particular waste streams if the volume is sufficient to make it economically viable!

-

Excellent detection with monochrome

USB cameras. -

Standard LED lights.

-

Very limited computer power needed.